charpy impact test origin|charpy impact test failure : manufacturing Charpy impact testing is a low-cost and reliable test method which is commonly required by the construction codes for fracture-critical structures such as bridges and pressure vessels. Yet, it took from about 1900 to 1960 for impact-test .

2 dias atrás · Documento traz relatos de incitações de ataques e motins contra casal de homens trans, entrega de alimentos estragados e xingamentos desde 2019. Caso .

{plog:ftitle_list}

Resultado da Cow Country Cottage. A family needs help building a country cottage on their new lot in the middle of cow country. Mika and Brian look to transform their mud paddy into a field of dreams, but a surprise could completely derail this home's 100 day due date. See Tune-In Times.

1.2.3.1 Charpy impact. The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the .

This contribution attempts to present a brief historical review about the general development of material testing, starting at the beginning of the intense industrialisation in the . The impact-test procedure seems to have become known as the Charpy test in the first half of the between Stockton and Darlington on 27 September 1825, whereas the first .

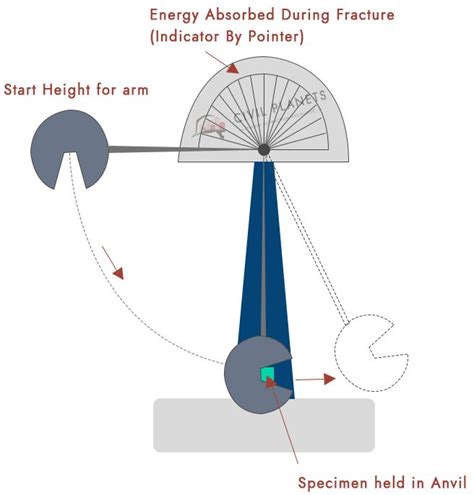

The Charpy impact test, also known as the Charpy V-notch impact test, measures the energy a material absorbs when it fractures under an impact load. A pendulum in a Charpy impact test .

The Charpy impact test, introduced by Georges Augustin Albert Charpy (1865–1945) in 1901, is widely utilized for efficiently evaluating the toughness of materials. This method assesses the energy absorbed by a .Charpy impact testing is a low-cost and reliable test method which is commonly required by the construction codes for fracture-critical structures such as bridges and pressure vessels. Yet, it took from about 1900 to 1960 for impact-test . Charpy impact testing is a low-cost and reliable test method which is commonly required by the construction codes for fracture-critical structures such as bridges and pressure . The Charpy impact test (DIN ISO 179) measures impact strength by taking into account how much energy is absorbed by a material when it is exposed to an impacting force.

Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact .The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away .

The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness of materials, particularly metals. His .

what is the charpy test

history of charpy testing

compression test chevy silverado 2500

Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a). Charpy impact test standards. ASTM E23, ASTM D6110, ASTM A370, ASTM D256. ISO 13479, ISO 148-1. EN 10045-1, EN ISO 179-1 Izod impact testing. While Charpy impact testing is widespread for metals, Izod impact testing is more often used for plastics and other softer materials. In Izod testing, the notched specimen is positioned vertically instead .The Charpy impact test is particularly essential for materials used in parts that are subjected to strong impact or high pressure, such as those used in the power generation units and piping of nuclear power plants. . The Charpy impact test is used to find the amount of absorbed energy, meaning the amount of energy which was expended in .

History of Charpy Impact Testing The origin of some common mechanical test-ing that we perform today can be traced back to research and discoveries from the 1800s. In that era there was an International Asso-ciation for Testing Materials that would meet every 2-3 years in various cities around the world. By 1913 it had 2,682 members includ- An Izod impact testing apparatus — which is essentially identical to a Charpy impact testing machine — is used to determine Izod impact strength. The primary differences between the Izod and Charpy impact tests are the size of the test specimen, how it is restrained, and which side is struck by the pendulum hammer. . This definition explains the meaning of Charpy Impact Test and why it matters. #.. Mitigating Corrosion Under Insulation and Supporting the Longevity of Industrial Pipe Insulating Systems . Charpy impact testing is one of the most popular methods used to evaluate the toughness of a material, which is typically measured in ft-lbs.

Charpy-impact-test definition: A test of the impact strength of a material , used to determine its relative ductility or brittleness . The test is executed by swinging a large, heavy hammer on a pendulum from a predetermined height. The hammer fractures the material sample, usually a block of a certain size with a notch cut in it. ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the fracture behavior changes as the temperature drops and the fracture type changes from ductility to brittleness.

Abstract Charpy impact testing is a low-cost and reliable test method which is commonly required by the construction codes for fracture-critical structures such as bridges and pressure vessels. yet, it took from about 1900 to 1960 for impact-test technology and procedures to reach levels of accuracy and reproducibility such that the procedures could be broadly .

The objective of the Charpy impact test to ISO 148-1 is the determination of the impact energy and determination of the impact strength of a metal. The test indicates whether the metal is tough or brittle. In addition, the tough/brittle transition can be determined based on the temperature. Impact strength is a material characteristic value.The Charpy impact test is still used throughout sectors to assess material toughness, from construction and manufacturing to engineering and beyond. This test offers practical insights into how materials respond to sudden, dynamic impacts. Even as businesses change, the Charpy impact test is still a valuable and essential tool.The value of energy absorbed is read directly from a dial on the machine. A typical impact testing machine is shown in Figure. 1. Figure 1. Schematic of a Typical Charpy Impact Testing Machine. In carrying out a test, the specimen is loaded into the anvil with a pair of special tongs that facilitate location of the specimen in the machine.

Video shows what Charpy impact test means. A test of the impact strength of a material, used to determine its relative ductility or brittleness. The test is . A decade before an iceberg shattered the hull plates of the Titanic and half a century before a plague of brittle fractures started sinking Liberty ships during World War II, scientists in the United States and France had devised a . Metallic materialsmeasuring impact energy are: Charpy Test and Izod Test.Charpy impact test is a low-cost and reliable test method, which is commonly required by the construction codes for fracture critical structures such as bridges and pressure vessels. Charpy impact test was developed in the 1960's as a method of determining the relative impact strength of .

The Charpy impact specimens of each material are immersed in a bath for 10 minu tes to reach thermal equilibrium at five separate temperatures ranging from 110oF (-79oC) to 212-oF (100oC). The specimens are quickly transferred to the Charpy testing machine, fractured, and the impact energy is measured. After

History of Charpy Impact Test . In 1896, S. B. Russell introduced the concept of residual fracture energy and developed a pendulum fracture test, initially measuring un-notched samples. Subsequently, in 1897, Frémont introduced a similar test utilizing a spring-loaded machine to measure the same phenomenon.In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and .

Explore the Charpy impact test method for metallic materials as specified by the European EN 10045 standard. Understand the test's purpose, procedure, and the significance of the energy absorbed in joules. Learn about the designations, test pieces, and testing machines used. The use of the pendulum hammer, proposed by RUSSELL in 1897, was popularized by the work of CHARPY, whose name has remained attached to the impact test. The CHARPY test is widely used today, both .

To determine the material resistance to impact from a swinging pendulum. Apparatus Required. Charpy testing machine, a rod of mild steel and a rod of carbonate steel. Charpy Test Specimens. Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be :

CHARPY V-NOTCH TEST. The impact-pendulum test method and associated equipment in nearly its current form was first developed more than a century ago. And while the basic concept behind this testing method is generally credited to two different engineers, S. B. Russell (1898) and G. Charpy in (1901); the test is now known by only the latter's name. Since 100 years the Charpy-Test (George Charpy 1865-1945) belongs to the standard methods in materials testing. After a retrospectice on the origin of this test, the article shows the important . A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after impact. An instrumented striker, on the other hand, has force sensors on the striker'

compression test chiropractic

history of charpy experiment

webFica então fácil de entender que é 1 e mais de 1.5 betano e o que significa: é uma aposta .

charpy impact test origin|charpy impact test failure